It was recently reported that the Hungarian government is also trying to pave the way for battery recycling plants by amending the law, and the Minister of Economy has been persuading several battery recycling companies in South Korea and China to invest in Hungary. According to a statement from the Ministry of Economy, since the EU’s 2023 regulation makes battery producers responsible for collecting and recycling all battery waste, but the country still has hardly any recycling plants, so this sector needs to be developed „to provide safe and environmentally friendly solutions for the large-scale recycling of used batteries.”

As for „safety”, anyone who has seen a battery recycling plant on fire or followed the events in Bátonyterenye and Szigetszentmiklós at the South Korean SungEel’s plants (exploding shredder, deaths, workers exposed to toxic substances) does not need much explanation. Due to the ageing process of the Li-ion batteries and the internal changes that occur during charging, the older the battery, the greater the risk of ignition. Let us now look at the term „environmentally friendly” in relation to the regular functioning of the battery factories.

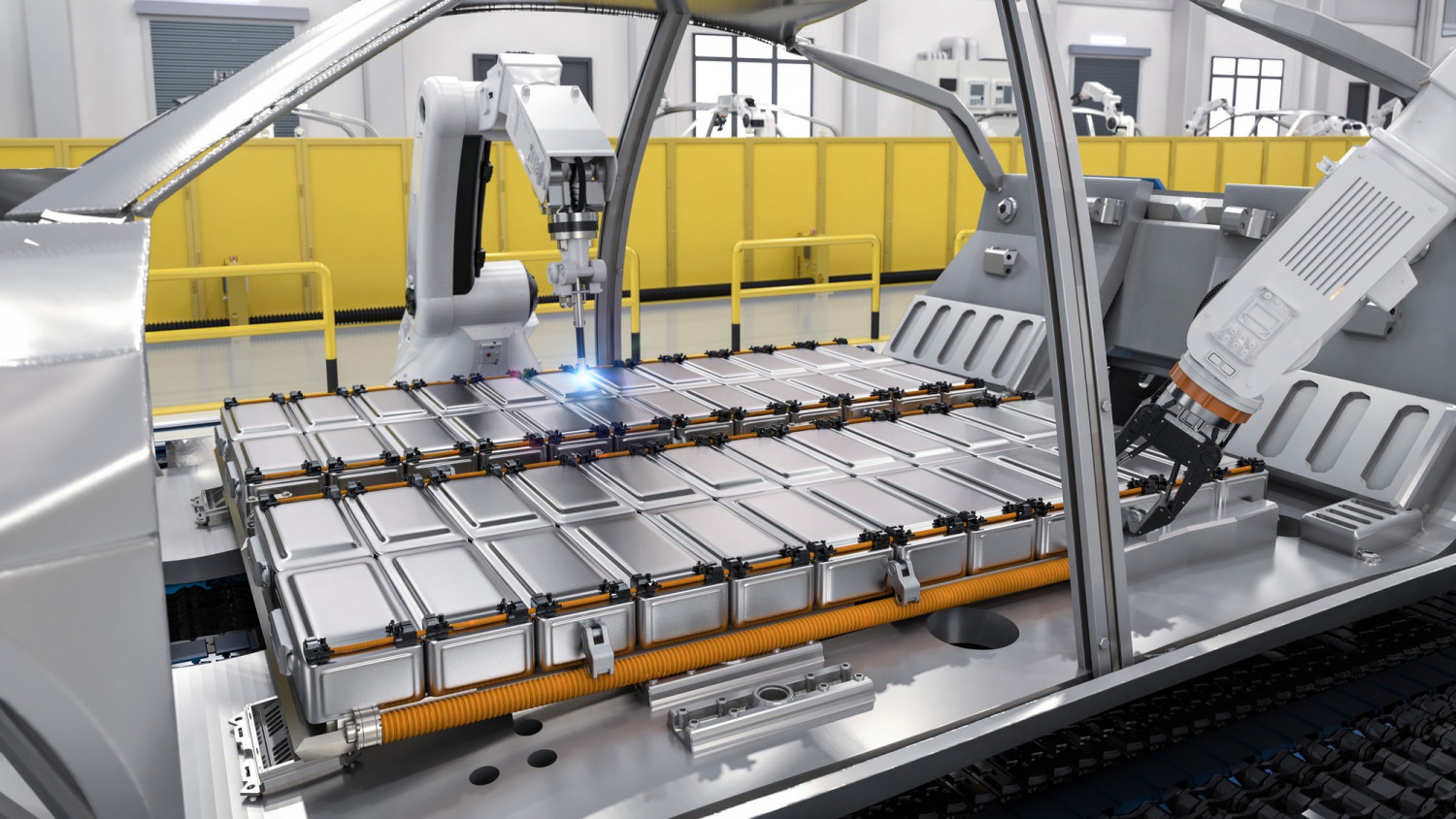

Recycling currently uses two basic technologies after the discharge of used batteries: 1. energy-intensive pyrometallurgy (incineration, pyrolysis, 1000-1600 oC), which allows the recovery of valuable cathode-active substances. Here 46 different gas products were identified, due to the evaporation and degradation of the electrolyte and the pyrolysis of the separator and binder. 2. hydrometallurgy (400-600 oC), in which, after removal of the electrolyte and binders, inorganic or organic acids are used to dissolve the metallic components, followed by component separation. In this way, lithium, cobalt, nickel and other metals are recovered in sufficient purity to be reused in production. This technology is water and chemical intensive and produces large amounts of industrial wastewater. It is worth noting that the future would be the so-called direct technology, which, following the introduction of standardised battery systems, is based on a ‘parts replacement’ philosophy. Encouraging R&D results have already been achieved in this area, minimising emissions.

Some of the substances that are released during recycling are much less well known than heavy metals or the solvent NMP. These are the per- and polyfluorinated alkyl substances (PFASs), which have found a wide range of applications and are present in products from many industries, e.g. in waterproof textiles, food packaging, tableware, paints and as flame retardants or electrolyte additives in lithium-ion batteries. In the event of fire, polyvinylidene difluoride (PVDF) used in battery factories produces several toxic fluorinated gases (Semcorp, Samsung, SK, CATL, Bamo use PVDF as a binder). PFAS are stabile, “forever” materials, slowly cumulating in human body or in the environment. According to a recent European survey, only 29% of people know about these substances, but 84% of those who are informed are concerned about their environmental impact. The European Chemicals Agency (ECHA) has proposed the restriction of more than 10,000 of these compounds by 2023, and this process is underway in various sectors.

A study details the fate of PFAS compounds at the stages of the Li-ion battery recycling process. For example, the much lower temperature used in hydrometallurgy compared to pyrometallurgy is unfavourable for the mineralisation of PFAS components, but at the same time promotes the formation of new PFAS compounds.

Every time a new battery manufacturer or recycling company invests in the country, it is said that „it is a closed system”, almost nothing is released into the air, waste water, the limits (if any) are strict, etc. It is possible that such a plant exists, but for the time being the examples of Göd and other domestic factories, but also international experience contradict this.

An article published in the prestigious journal Nature in July 2024 informed about important results. Between January and October 2022, an international team of researchers sampled surface water, groundwater, tap water, snow, sediment and soil samples at 87 different sites in the USA and Europe. The sampling locations were near Li-ion battery factories. A subset of PFAS substances (bis-FASI sulfonimides) were detected in all samples, even in leachate from landfills. The presence of the chemicals in snow, for example, suggests that these move easily in the atmosphere, they have been found in Chinese seawater and other remote areas not close to production plants.

Toxicity data have shown that bis-FASIs alter the behaviour and basic energy metabolism of aquatic vertebrates and invertebrates even at low concentrations. In other words, there is evidence that the aquatic fauna is being harmed by Li-ion battery production (as well). Based on this study, it is likely that the concentrations of PFAS compounds in soil, groundwater, surface water, sewage residues and landfill leachate will increase, and trigger human and environmental problems.

In addition to PFAS substances, heavy metal compounds, NMP and other solvents are likely to be released into wastewater and, depending on the efficiency of the water treatment technology used, into surface and groundwater, not only from battery production but also from hazardous waste management. Thus, it can be said that the massive development of the battery industry has the potential to harm the living creatures of our waters, all members of the food chain and ultimately even humans to an unknown extent. We do not know either where the contaminated sludge filters, protective gloves and rags that are considered serious hazardous waste end up from the factories. What we do know is that hazardous waste is sometimes classified as non-hazardous, whether legally or illegally, and that when abandoned mines are filled up, strange things do end up in the waste. Add to this the wetlands that have been covered by the construction of the factories, the particulate matter, carbon dioxide and water vapour that are released into the air by their operation, and the nitrogen oxides that contribute to acid rain (significant increases in these have already been documented in Göd and Komárom), and you can see the serious damage to the ecosystem (and at the expense of Hungarian taxpayers, since the factories in Asia receive huge direct and indirect state subsidies of around HUF 1500 billion).

We have to agree with the environmental chemists who wrote the Nature article that rigorous and complex life-cycle assessments and calculations would be needed to ensure that the reduction in CO2 emissions (greening) is not offset by an increase in the emissions of persistent pollutants. Otherwise, we have a classic case of ‘unintended substitution’ (replacing bad with worse) and the opportunity for sustainability is missed.

This kind of cost-benefit analysis has never been done in our country. Rather, it is the forced implementation – at any cost – of an uncoordinated and ill-considered strategy that might have seemed good four years ago. After all, if we import a lot of battery factories from Asia, they will need a lot of raw materials (electrolyte, cathode, NMP, separator film, etc.). The large amount of scrap left over from production and the used batteries that will be produced later on will also require recycling plants (otherwise they will be illegally dumped in abandoned warehouses). The battery train is moving on the fast track: „this year, we need to decide which companies can start investing in which locations,” the economy minister said about the Asian battery recyclers.

Choosing such sites will not be easy, nor is it easy in other European countries because of public protests. In Poland, SungEel wanted to invest in the Silesian municipality of Złotoryja in early 2021, which led to significant public protests over environmental and health concerns. In the end, the company abandoned the investment and built the plant in Bukowice in 2022. In Thuringia, Germany, SungEel is facing strong public opposition in its second desired location and is unable to start the investment, but most recently, local residents in the province have also risen up against the Finnish battery recycler Fortum. A referendum near Ostrava in the Czech Republic rejected a South Korean greenfield battery factory in the summer. Hungarian residents have also protested in Alsózsolca, Sóskút and Heves, but government decrees and “national priority investment” method could force through battery recycling plants. In this case, the already knocked out Hungarian nature and environmental protection will once again receive a targeted blow from the government, which may benefit some business circles in the short term, but the picture that emerges in the longer term is depressing.

It is a fact that Hungarian companies can hardly get involved in the battery production process and Hungarian added value is low, but it would be good to improve this at least in the field of research and development. There are initiatives in this respect in the framework of the Innovation Partnership Programme with South Korea, for the implementation of which the Korean Development Institute commissioned a 40-page study for the Hungarian government in 2023 entitled „Development of a life cycle management and traceability system for batteries”. This is available only on the Korean Institute’s website, in English. The study proposes the development of such a system and the establishment of a Korean-Hungarian cooperation centre, to be set up by 2028, to analyse battery materials and production (also important for future recycling) and to acquire instruments to test and improve battery performance. Environmental impacts are only mentioned in the study in relation to EU regulation (ecological footprint) and there is no mention of the irregular, polluting and unsafe activities of South Korean battery factories in Hungary. As this is a Korean-Hungarian centre, it will cooperate with the Korean factories, and its staff will probably not even be allowed into the Chinese factories.

However, in parallel and in conjunction with technological developments, supporting Hungarian R&D would be a pioneering step internationally to mitigate or eliminate the expected negative ecological and environmental impacts of battery production and recycling. This would require an accurate and comprehensive external monitoring system, thorough and transparent documentation, appropriate instrumentation and well-trained professionals. All this would allow (at least in the future or in other countries) to reduce emissions, increase Hungarian added value and provide opportunities for the application and development of new, state-of-the-art knowledge.

Andrea Éltető

Thanks are due to Professor Emeritus Gyula Záray (HUN-REN Centre for Ecological Research) for his help in navigating through the chemical compounds.

Translation of the post of KRTK Portfolio-blog, published on September 20, 2024 at: https://www.portfolio.hu/krtk/20240920/jelentos-mertekben-szennyeznek-a-magyarorszagi-akkumulatorgyarak-de-lenne-erre-megoldas-710973